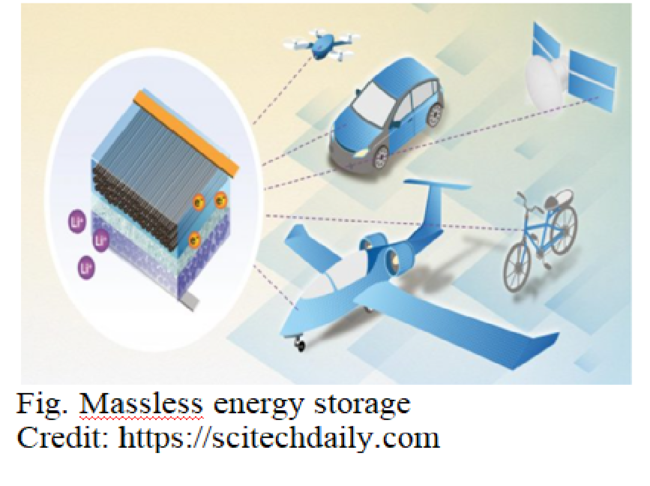

Storage of energy is the need and is always stored in a system having mass. Batteries, the wheels of present day, technology are the example of energy storage for its (energy) use in required form, desired time, place and amount/rate. Batteries are a mass energy storage systems, coming with various limitations like, weight, size, cost, and life span. Efforts are always directed to develop batteries with characters like light weight, cost effective, small in size, durable, with more capacity. Now, efforts are also being directed towards massless energy storage and when it will be practical, it could revolutionize the battery or energy dependent applications like electric vehicle and aircrafts. Recently, scientists have made a massless structural battery 10 times better than before. The battery cell performs well in structural and energy tests, with planned further improvements. Structural batteries reduce weight and could revolutionize electric cars and planes.

A structural battery refers to an energy storage device that can also bear weight as part of a structure-like if the studs in home were all batteries, or if an electric fence also held up a wall. The structural battery uses carbon fiber as a negative electrode, and a lithium iron phosphate-coated aluminum foil as the positive electrode. The carbon fiber acts as a host for the lithium and thus stores the energy. Since the carbon fiber also conducts electrons, the need for copper and silver conductors is also avoided – reducing the weight even further. Both the carbon fiber and the aluminum foil contribute to the mechanical properties of the structural battery. The two electrode materials are kept separated by a fiberglass fabric in a structural electrolyte matrix. The task of the electrolyte is to transport the lithium ions between the two electrodes of the battery, but also to transfer mechanical loads between carbon fibers and other parts.

Researchers from Chalmers University of Technology and KTH Royal Institute of Technology in Sweden reveal how their “massless” structural battery works. To make the new structural battery, the scientists layered a buffer glass “fabric” between a positive and negative electrode, then packed it with a space-age polymer electrolyte and cured it in the oven which results in a tough, flat battery cell that conducts well and holds up to tensile tests in all directions. The cell consists of a carbon fiber electrode and a lithium iron phosphate electrode separated by a fiberglass fabric, all impregnated with a structural battery electrolyte for combined mechanical and electrical function. Three structural batteries have been connected in series and laminated as part of a larger composite laminate. Each structural battery cell has a nominal voltage of 2.8 V. The laminate has a total voltage of 8.4 V and a stiffness in the plane of just over 28 GPa.

The main use case is for electric cars, where a literally massive amount of batteries take up a ton of room and don’t contribute to the actual structure of the car. In fact, these cars must be specially designed to carry the mass of the batteries. But what if the frame of the car could hold energy? The new battery has a negative electrode made of carbon fiber, and a positive electrode made of a lithium iron phosphate-coated aluminum foil. They are separated by a fiberglass fabric, in an electrolyte matrix. Due to their multifunctionality, structural battery composites are often referred to as ‘massless energy storage’ and have the potential to revolutionize the future design of electric vehicles and devices. It is called ‘massless’ energy storage because rather than add extra weight to the vehicle, it becomes part of the load-bearing structure – the battery’s weight essentially vanishes. For EVs to be more efficient, better energy storage is required, but the overall weight needs to be maintained or reduced.

The batteries in today’s electric cars constitute a large part of the vehicles’ weight, without fulfilling any load-bearing function. The first attempt to make a structural battery was made as early as 2007, but it has so far proven difficult to manufacture batteries with both good electrical and mechanical properties. A structural battery, on the other hand, is one that works as both a power source and as part of the structure – for example, in a car body. This is termed ‘massless’ energy storage, because in essence the battery’s weight vanishes when it becomes part of the load-bearing structure. Calculations show that this type of multifunctional battery could greatly reduce the weight of an electric vehicle. Structural battery composites cannot store as much energy as lithium-ion batteries, but have several characteristics that make them highly attractive for use in vehicles and other applications. When the battery becomes part of the load bearing structure, the mass of the battery essentially disappears. Thus, super light electric bikes and consumer electronics could soon be a reality.